Chapman tells you what problems to pay attention to when designing high-precision plastic molds

High-precision plastic molds have relatively high requirements for design, and the complexity of mold design is higher than that of ordinary molds, so before confirming the start of construction, all processes must be determined, so that it will not be processed. problems occurred during the process. So what should be paid attention to when designing high-precision plastic molds, Chapman's engineers will take you to understand.

1. The most important step is to conduct a feasibility analysis of the plastic product drawings provided by the customer, determine the mold structure, and strictly regulate the product design process. Pay attention to complete it carefully and carefully, which will also save a lot of time for the next step.

2. According to the analysis of the product expansion diagram of the precision injection mold design, and prepare various materials required for the design of the precision injection mold. Preparing materials according to the product unfolding diagram can improve the efficiency and the accuracy of the material preparation amount, and reduce the error, which is conducive to the rapid completion of the design work.

3. Determine the mold opening direction and parting line position of the high-precision plastic mold; each plastic product needs to determine its mold opening direction and parting line at the beginning of the design to ensure that the core slider mechanism is minimized , to reduce the effect of the parting line on the appearance. After determining the mold opening direction of the high-precision plastic mold, try to make the product reinforcement, bayonet, protrusions and other structural designs consistent with the mold opening direction to avoid core pulling, reduce seams, and extend molding time.

4. After determining the mold opening direction of the high-precision plastic mold, an appropriate parting line can be selected to avoid the undercut phenomenon in the mold opening direction and improve the appearance and performance of the mold.

5. Properly adjust the draft angle of the high-precision plastic mold to avoid damage such as white edges, deformation, and cracks on the top of the product. In the design of deep cavity structure products, the slope of the outer surface should be larger than that of the inner surface as much as possible to ensure that the plastic injection mold core will not move, so as to obtain a uniform product wall thickness, while ensuring the material strength and product opening time.

6. Each different plastic has a certain range of wall thickness, generally 0.54 mm. When the wall thickness exceeds 4 mm, it will lead to problems such as excessive cooling time and shrinkage of plastic products. Consider changing the product. structure. Uneven wall thickness can cause surface shrinkage. As well as air holes and weld lines. In addition, the rational use of reinforcing ribs can increase the rigidity of the product and reduce deformation.

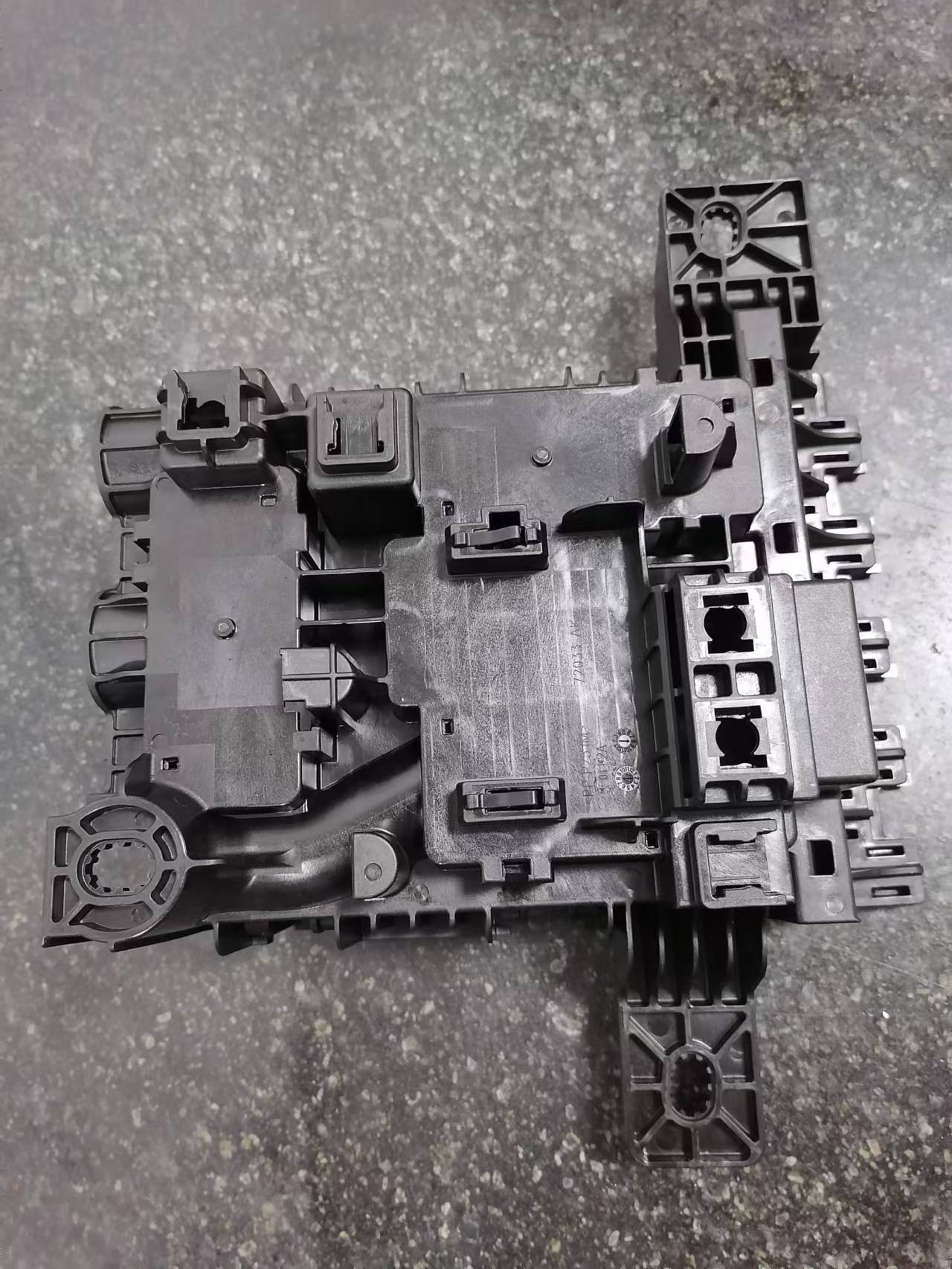

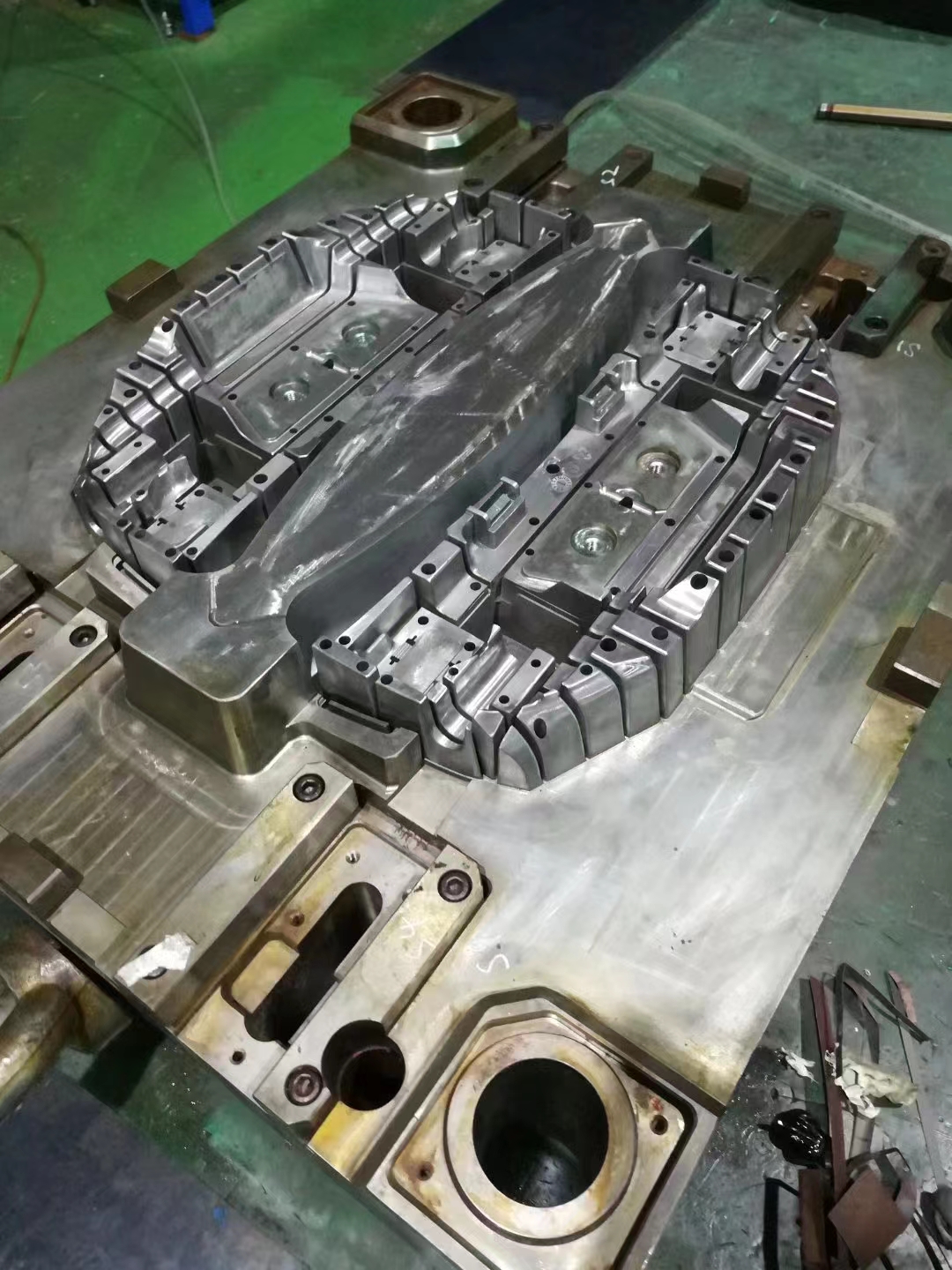

The above are the issues that need to be paid attention to when designing and manufacturing high-precision plastic molds. High-precision molds are a very high-tech project in both design and processing. All must find a professional mold design and development company. Chapman is a service focusing on mold development, design and manufacturing, product injection molding and other fields. We have a professional mold design team and high-precision mold manufacturing equipment. The businesses involved are: mold development and manufacturing, plastic mold design, mold injection processing, injection molding processing and other businesses. Our services cover the shell injection processing and precision mold injection production in the automotive field, medical equipment field, beauty equipment field, digital field, electronic equipment and other industries.

Contact Chapman today for high precision mold injection production.

For more information, you can contact us at info@chapmanmaker.com.

Post time: Nov-23-2022